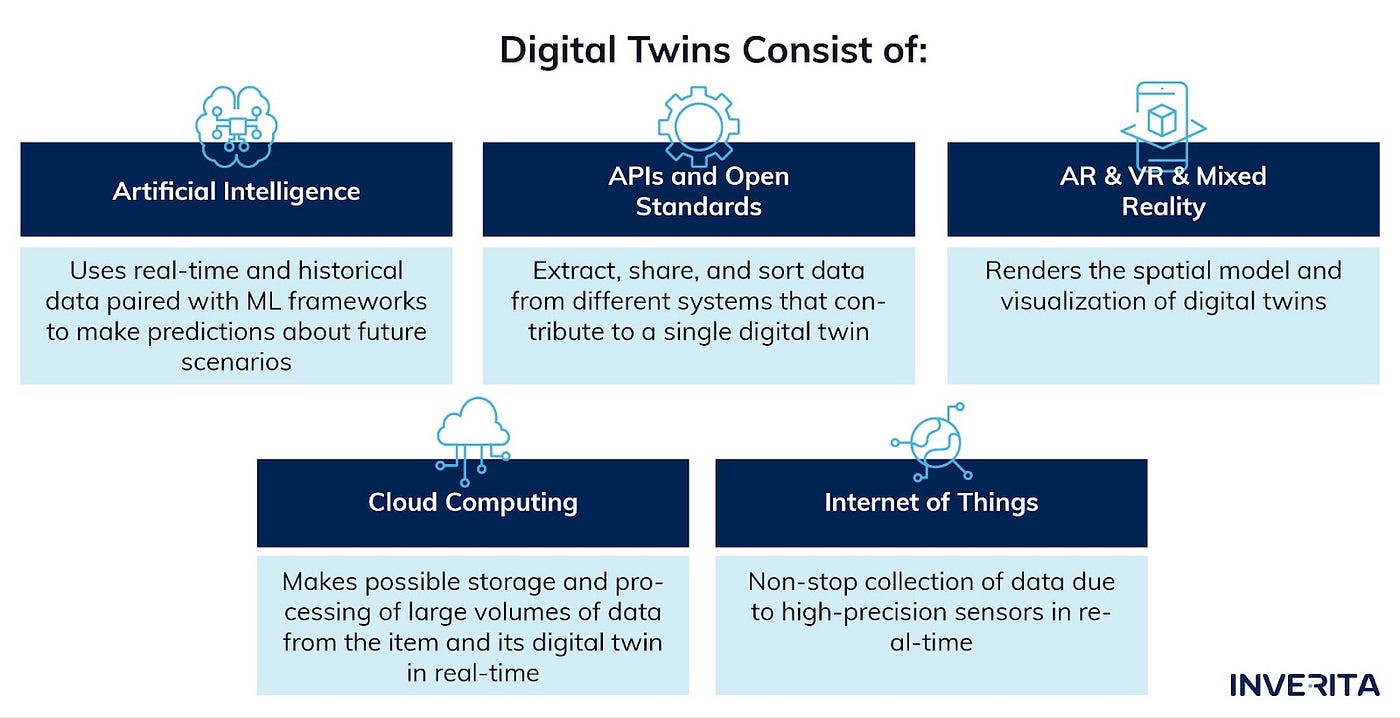

4. Internet of Things

The IoT global market is growing at a rapid pace with a cumulative annual growth rate of more than 32%. Its implementation in the logistics sector is very broad and enables logistics companies to gain elevated results. Here are some of the areas of its usage:

- Location and Route Management

The location and route of trucks, as well as driving activities, can be monitored in real-time from remote locations. The real-time alarm systems can send notifications about any weather anomaly, or accident on a freeway, identify time-delaying barriers, and more.

- Warehousing and Inventory Tracking

RFID tags and sensors enable companies to easily track their inventory items, their status, and their position. It allows companies to efficiently locate their items, ensure their safe storage, and prevent losses.

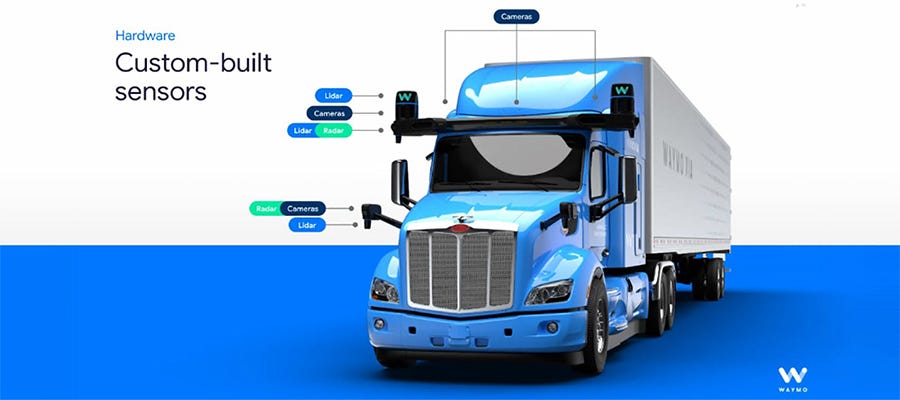

Autonomous vehicles are becoming increasingly popular and some logistics giants are already using them. Traditional auto industry players have embraced some of the IoT elements as a component of their development strategy, whereas, relatively new entrants like Tesla, Google, and others are actively using their own patent AI and IoT and manufacturing techniques to develop autonomous vehicles.

Drones can ensure automated process execution and quick delivery of goods, especially to people in remote areas. Amazon has already unveiled the use of drones for delivering ordered items.

The predictive applications of IoT help companies to detect defects in truck performance before they become catastrophic. By measuring and analyzing parameters, companies get alerts about unexpected malfunctions, create effective inspection strategies, and reduce risks and downtime.

5. Cloud Logistics

Cloud computing enables logistics companies to access, keep, share, and secure data. Therefore organizations are either migrating their existing transportation management systems to the cloud or investing in cloud-based TMS software. Such TMSes are accessible from anywhere in the world as they require only an internet connection, consolidate data from different internal and external sources, use advanced analytics, and automate manual processes which streamline workflows.

6. Artificial Intelligence

Most logistics companies have already shifted to a proactive and predictive paradigm with AI. Artificial intelligence transforms all aspects of logistics, and actually, every point mentioned in this blog is somehow connected to it.

Though we haven’t mentioned customer experience yet. AI personalizes customer experience, increases loyalty, and boosts retention. Through robust data analysis, companies can deliver goods before their customers have even ordered them. Drawing predictions with the help of AI, analyzing browsing and purchase history, weather data, and social media chatters, companies can predict the next order a customer will make. Not to mention, demand prediction and shortening delivery time.

7. 3D Printing

3D printing or Additive Manufacturing is believed to be one of the most revolutionary logistics technology trends. In 2019, the global AM market reached $10 billion and it’s expected to grow every 3 years. The portable nature of the technology will enable businesses to supply products to local markets faster, tailor offerings to customer-specific requirements, save on production costs, and reduce the carbon footprint.

L’Oréal, for example, has been one of the pioneers in 3D technology implementation. The brand leverages the technology for functional prototypes, components for automation lines, spare parts, and limited series of 3D-printed packaging.