Machine Learning in Supply Chain

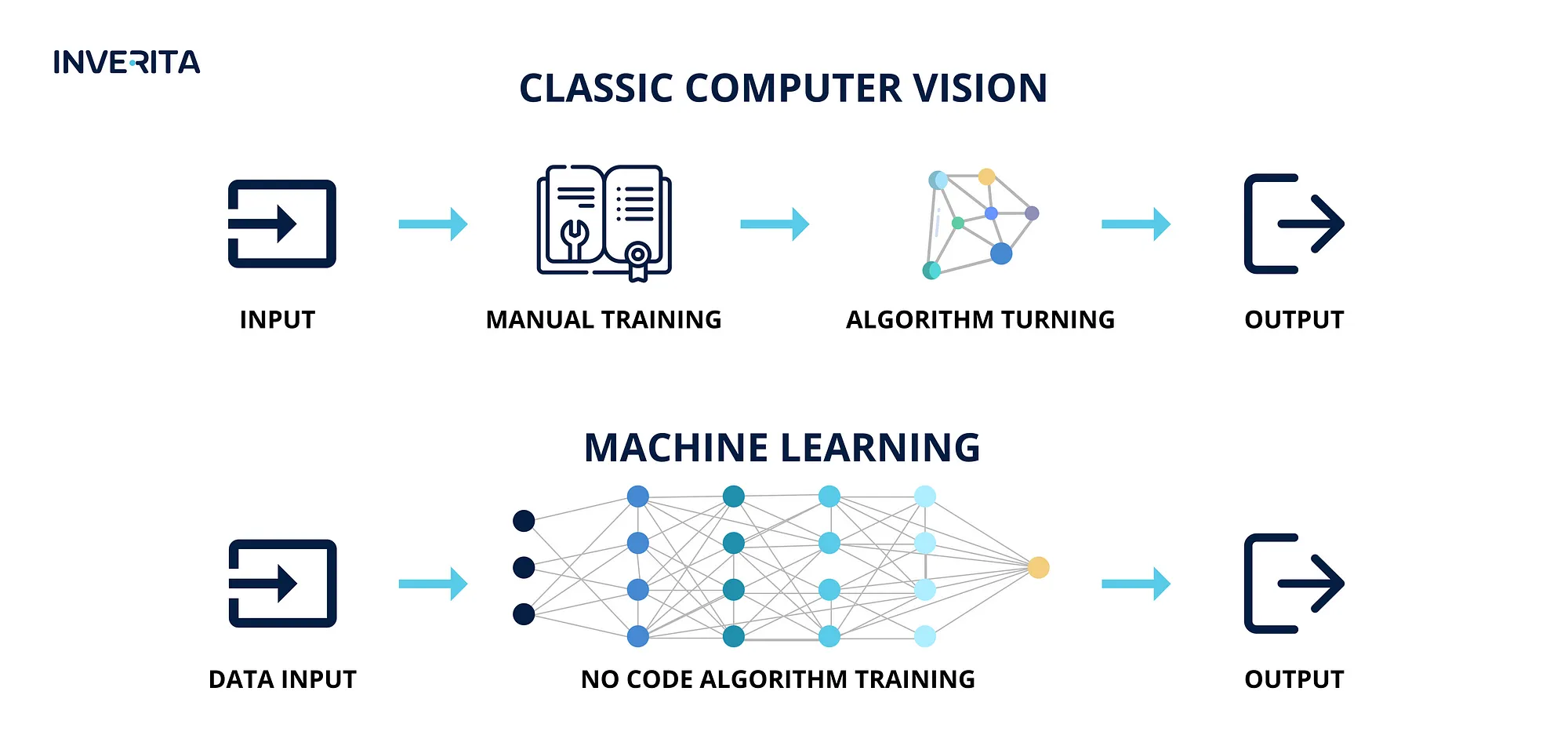

Machine Learning as a branch of Artificial Intelligence takes roots from its immersive ability to handle huge inputs of information, and even analyze the hidden patterns to make predictions and decisions where humans cannot. While the supply chain industry faces a lot of challenges to cope with information asymmetry, financial vulnerability, and organizational, transportation, and logistics inconveniences, Machine Learning algorithms used in supply chain management can easily solve these problems.

Use Cases of Machine Learning in Supply Chain

# Predictive analytics

Predictive analytics enables companies to control inventory levels to meet the customers’ demand while minimizing stock. It is similar to predicting the future, just instead of reading a palm, a mechanism prepares a mathematical model that represents the issue you’re interested in. Large amounts of data and piles of forecasting models are being tested until the one - the most reliable is established. With the help of such an analysis, organizations can forecast exchange rates and sales demand, adjust prices dynamically, and determine flawless shipping.

According to the 2024 MHI Annual Industry Report, 55% of supply chain leaders have accelerated the integration into digital technologies, in particular, predictive analytics.

Amazon, for instance, collects data from users while they are navigating the site. Through ML it analyzes the time each user spends on a particular page, the items they search for, wish lists, demographic details, etc. Hypothetically, if residents of New York usually order a lot of gloves in December, a local Amazon fulfillment center will receive a lot of them in advance and keep the gloves until the order is placed. This helps to cut delivery time just to one day, or even less depending on the distance between customer and Amazon distribution center. Actually, it’s the predictive analytics that helped Amazon stock their warehouses with a large number of facial masks when the pandemic had started.

# Warehouse Management

Being integrated into warehouse systems, Machine Learning automates manual work, is able to predict possible challenges in manufacturing, storage, or package processes, and reduces processing times. Every day new products arrive at warehouses, and they need to be stored and organized. Machine Learning analyzes the current location of items inside warehouses, and when new shipments arrive, they are just matched to the correct location. Computer vision also is able to control the working process of the conveyor belt and anticipate the moment when it gets blocked, reducing inefficiencies and delays. Robots are also programmed with the help of ML. Usage of robotics in warehouse management to a large extent simplifies and speeds up receiving, packing, transporting, and unloading operations.

Alibaba has one of the most up-to-date warehouses in terms of using technology. In their warehouses, up to 70% of work is done by robots. These robots are able to pick and carry up to 500 kilograms of goods at once. They are also equipped with special sensors so they don’t collide with each other. In case a robot needs to recharge, it goes to the nearest charging station.